Iimveliso

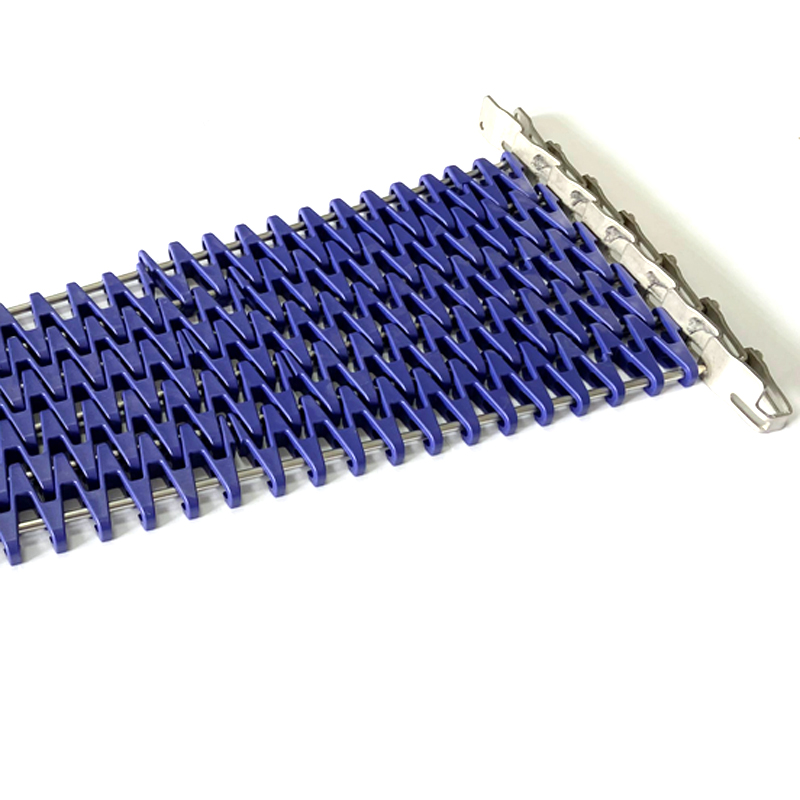

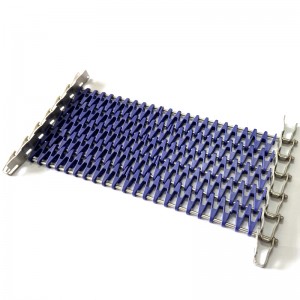

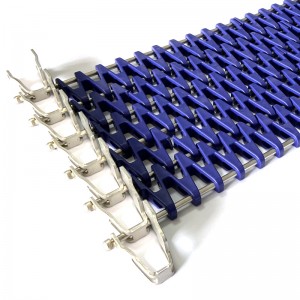

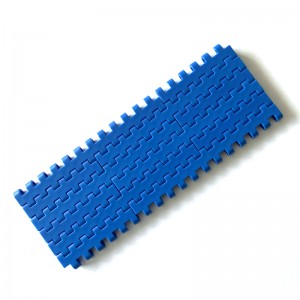

I-HAASBELTS Conveyor U193 Spiralox Flush Grid

Iiparamitha zeSprocket

| Uhlobo lweSprocket | Inani lamazinyo | Pitch ubukhulu | Ngaphandle kwedayimitha | A1 | Bore |

| H (mm) | C (mm) | mm | I-DF (mm) | ||

| 1-U193-17-40R | 17 | 207.4 | 215.8 | 98.0 | φ40 |

| 1-U193-17-50R | φ50 | ||||

| 1-U193-17-60R | φ60 |

Ukugcinwa kunye nokugcinwa kwe-spiral mesh belt conveyor

Ukuhlolwa rhoqo: Rhoqo jonga onke amacandelo okuhambisa ibhanti ye-spiral mesh, kubandakanywa iibheringi, amatyathanga, amabhanti anemesh, njl.njl., ukujonga ukunxiba, ukukhululeka, okanye ukungasebenzi kakuhle.Ngokukodwa kwiibhanti ze-mesh, ukungcola okufakwe kubo kufuneka kuhlanjululwe rhoqo ukuphepha ukuchaphazela ukusebenza kwabo okuqhelekileyo.

Ukuthambisa: Gcoba rhoqo iibheringi kunye namatyathanga okuhambisa ibhanti yebhanti ye-spiral mesh ukunciphisa ukukhuhlana kunye nokuguga.Kwiibheringi, igrisi yokuthambisa inokudityaniswa rhoqo, kwaye inani elipheleleyo lenaliti lingabhekisa kwi-2/3 yendawo yangaphakathi yebhokisi yokuthwala;Gxisa iibheringi ezimisiweyo kunye neeshafti kwigrisi yokuthambisa rhoqo ngezithuba ezi-4.

Ukucoca: Gcina ibhanti lebhanti elijikelezayo licocekile ukunqanda ukungcola nokungcola ekungeneni.Ngethuba lenkqubo yokuhambisa, izinto ezinkulu okanye izinto zetsimbi kwizinto eziphathekayo kufuneka zigwenywe ukungena kwi-conveyor ukuphepha umonakalo kwisixhobo.

Ukuqiniswa: Qwalasela ukuqiniswa kwamacandelo ahlukeneyo okuhambisa ibhanti elijikelezayo, kwaye uwaqinise ngexesha elifanelekileyo ukuba kukho ukukhululeka okufunyenweyo.

Ukugcinwa kwesixhobo sokuqhuba: Ukugcinwa rhoqo kwesixhobo sokuqhuba se-spiral mesh belt conveyor, kubandakanywa ukujonga ukusebenza kwe-drive motor kunye ne-reducer, kunye nokujonga ukunyanzeliswa kunye nokuthambisa ikhonkco lokuqhuba.

Ukugcinwa kokuvala: Emva kokuvala ixesha elide, kuyimfuneko ukuqhuba umatshini ngaphandle komthwalo ixesha elithile ukuze kuqinisekiswe ukuba onke amacandelo asebenza ngokufanelekileyo ngaphambi kokwenza umsebenzi womthwalo.Phambi kokumisa umatshini, zonke izinto ezingaphakathi kwi-conveyor kufuneka zihanjiswe ukunqanda umonakalo obangelwe zizinto ezishiywe kumhambisi ixesha elide.

Ulondolozo lothintelo: Ukuphuhlisa isicwangciso sogcino lothintelo rhoqo, kubandakanywa nokuhlolwa rhoqo, ukuthambisa, ukucocwa, njl.njl., ukuthintela ukusilela kwesixhobo ukuba kwenzeke.Ukuba kukho nasiphi na isandi esingaqhelekanga okanye ukungcangcazela kufunyenwe kwisixhobo, kufuneka kumiswe ngoko nangoko ukuze kuhlolwe kwaye kulungiswe ingxaki.

Ngokulandela amanyathelo okugcina apha ngasentla, ubomi benkonzo kunye nokusebenza kwe-spiral mesh belt conveyor inokuphuculwa ngokufanelekileyo, kwaye ukuvela kweziphene kungancitshiswa.

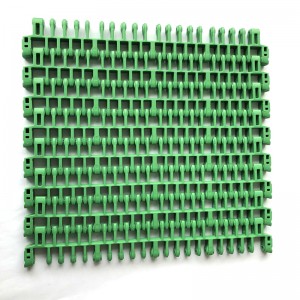

Inkqubo yokwenza imodyuli yebhanti yeplastiki yomnatha

Phuhlisa kwaye uyile izicwangciso zemveliso ezineenkcukacha ezisekelwe kwiimfuno zabathengi kunye neemfuno zezixhobo ezithile.

Yenza iimodyuli, khetha izinto ezifanelekileyo zeplastiki, kwaye utofe iimodyuli zeplastiki ngokuthelekisa oomatshini bokubumba inaliti.

Yahlula ngokobubanzi kunye nobude bomthengi ukwenza imodyuli yebhanti yeplastiki yomnatha.

IINDIDI ZEMVELISO

Gxininisa ekuboneleleni ngezisombululo zemong pu iminyaka emi-5.